Started from 1992. Over 30 Years Experience in Metal Weave Wire Mesh.

PRODUCT DETAIL

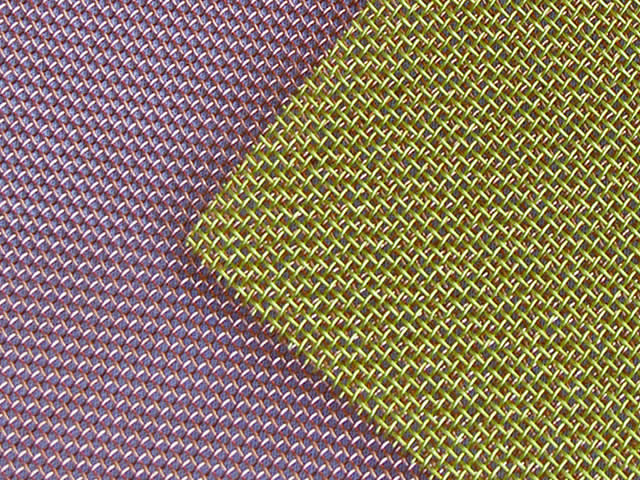

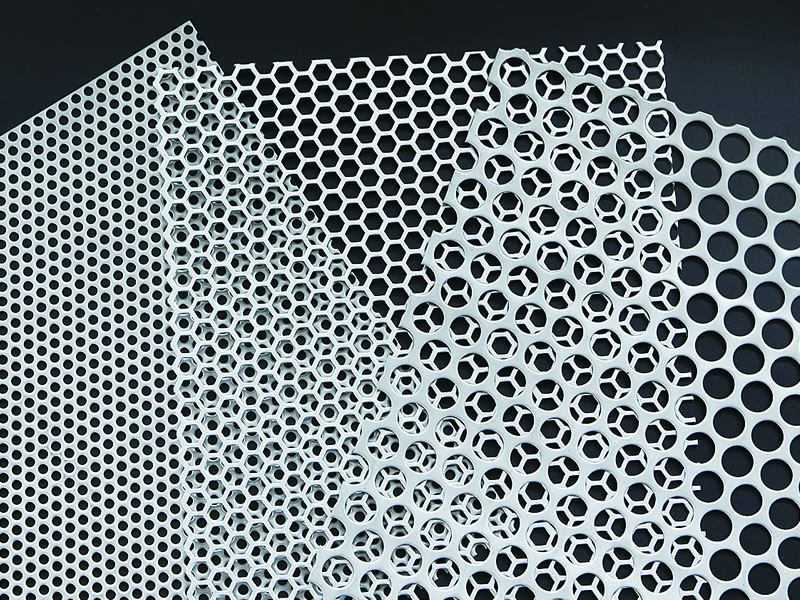

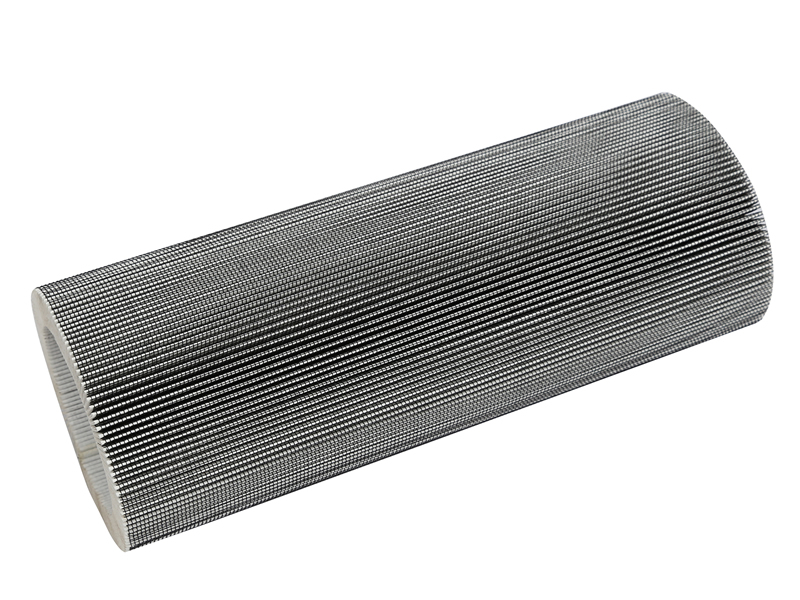

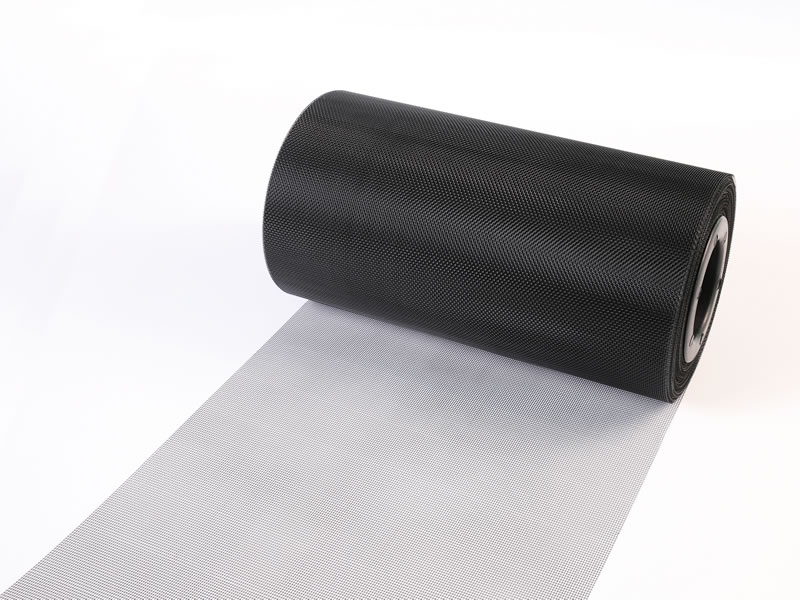

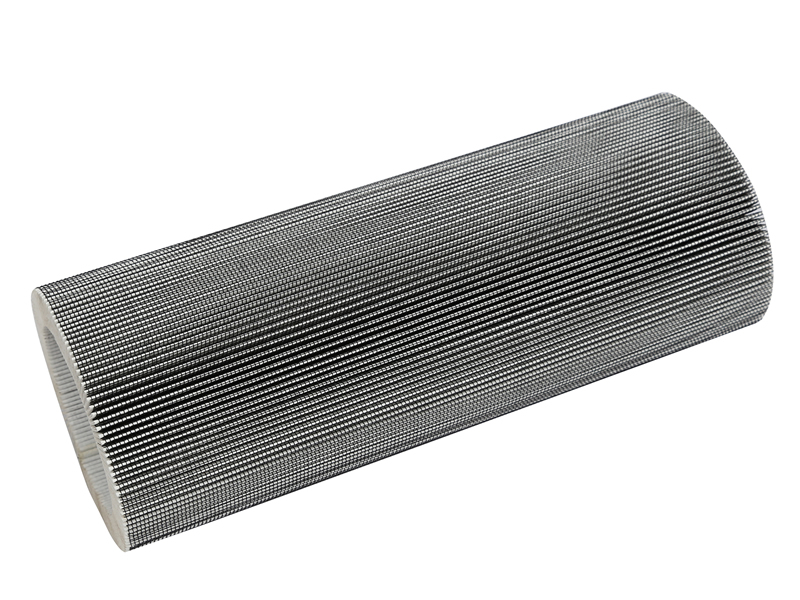

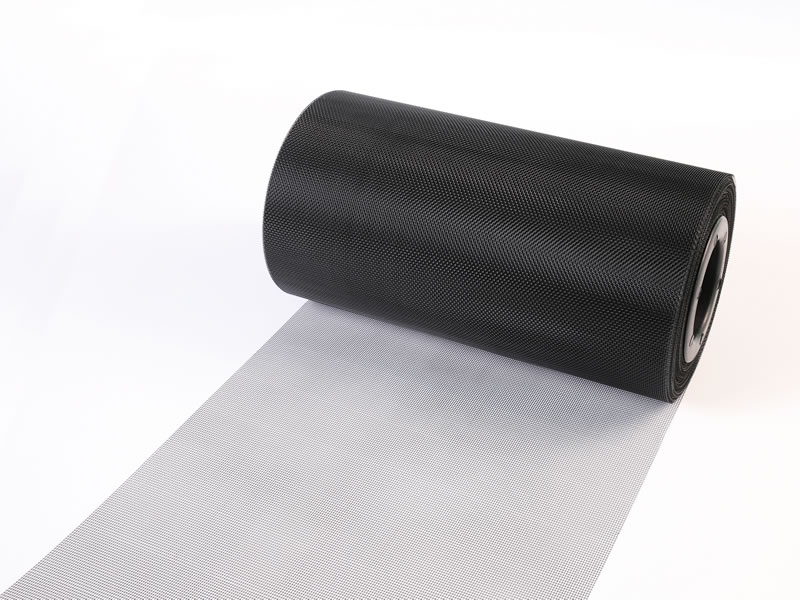

Epoxy Coated Wire Mesh made by varous metal wires with electrostatic powder spraying. Our company developed 4 production lines, significant achievemental have been made in both quality and environmental protection.

Material: Low carbon steel wire, stainless steel wire, aluminium wire and other wires.

Characteristic: Lightweight, resilient,uniform aperture, acid and alkali resistant, corrosion preventive, high temperature resistance, environmental protection, etc.

Application: Mainly used as support layer of hydraulic and air filters, also used for window screen and protective screen.

Color: Black, grey or customized specification.

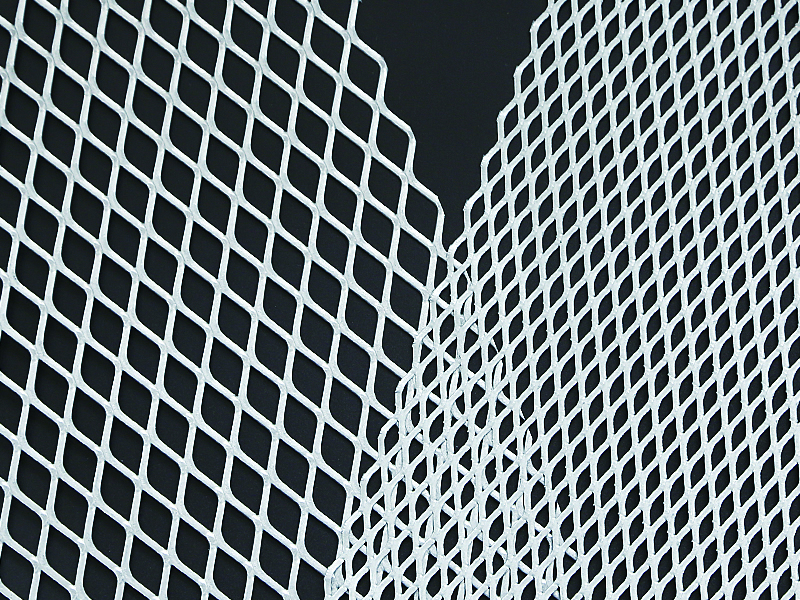

Material: Low carbon steel wire, stainless steel wire, aluminium wire and other wires.

Characteristic: Lightweight, resilient,uniform aperture, acid and alkali resistant, corrosion preventive, high temperature resistance, environmental protection, etc.

Application: Mainly used as support layer of hydraulic and air filters, also used for window screen and protective screen.

Color: Black, grey or customized specification.

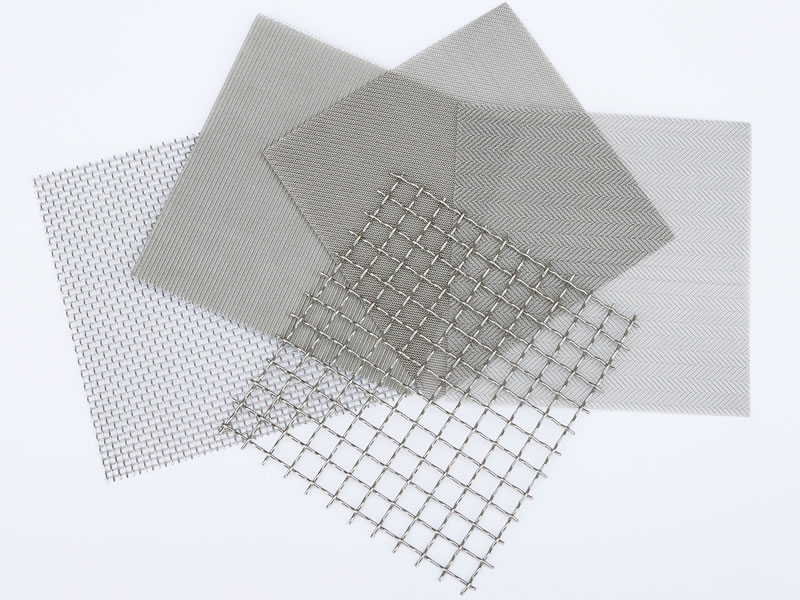

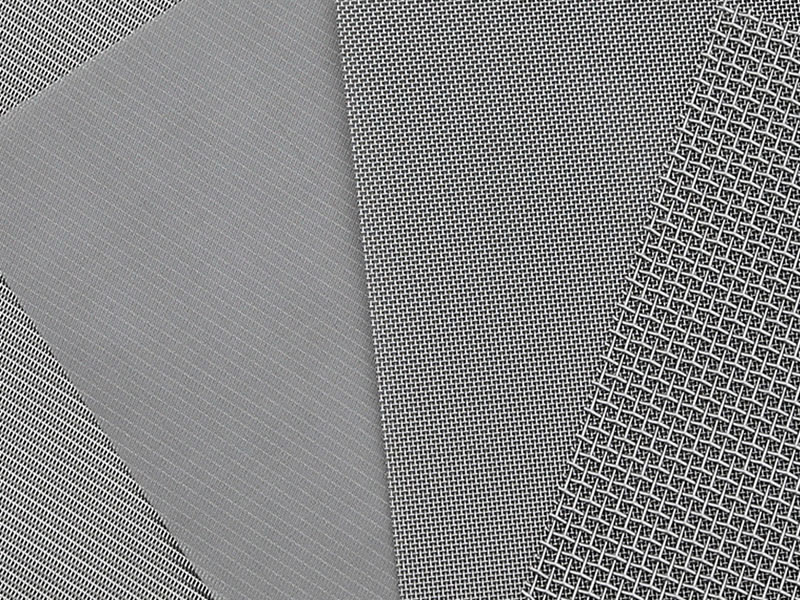

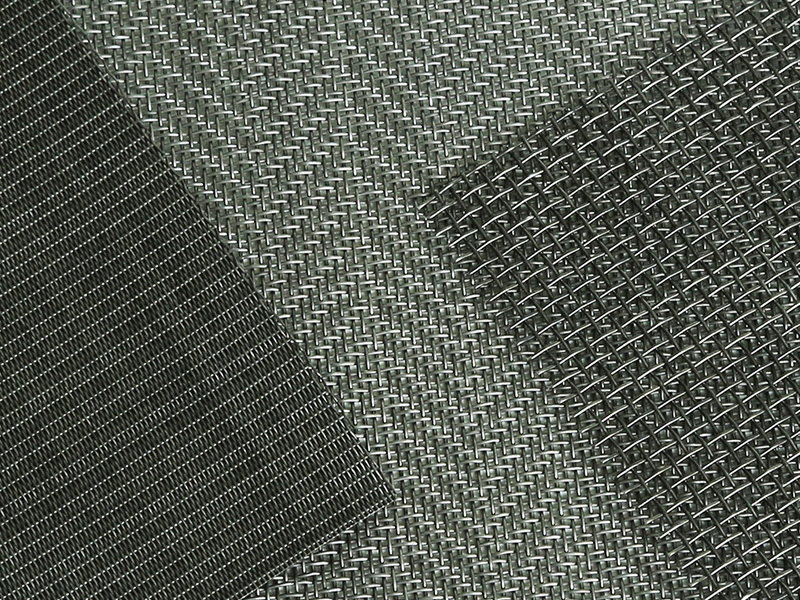

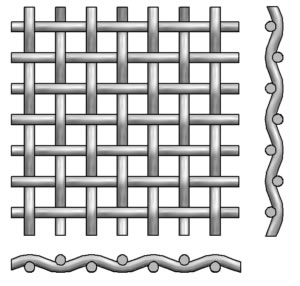

Plain weave

| EPOXY WIRE MESH(PLAIN STEEL) | |

| MESH(INCH) | WIRE DIA.(MM) |

| 18×14 | 0.18 |

| 20 | 0.18 |

| AVAILABLE IN WIDTH: 0.50M-1.30M | |

| EPOXY WIRE MESH(ALUMINIUM) | |

| MESH(INCH) | WIRE DIA.(MM) |

| 18×16 | 0.23 |

| AVAILABLE IN WIDTH: 0.50M-1.30M | |

| EPOXY WIRE MESH(STAINLESS STEEL) | |

| MESH(INCH) | WIRE DIA.(MM) |

| 13 | 0.70 |

| 14 | 0.60 |

| 14 | 0.70 |

| 16 | 0.40 |

| 16 | 0.60 |

| 18 | 0.23 |

| 22 | 0.18 |

| AVAILABLE IN WIDTH: 0.50M-1.30M | |

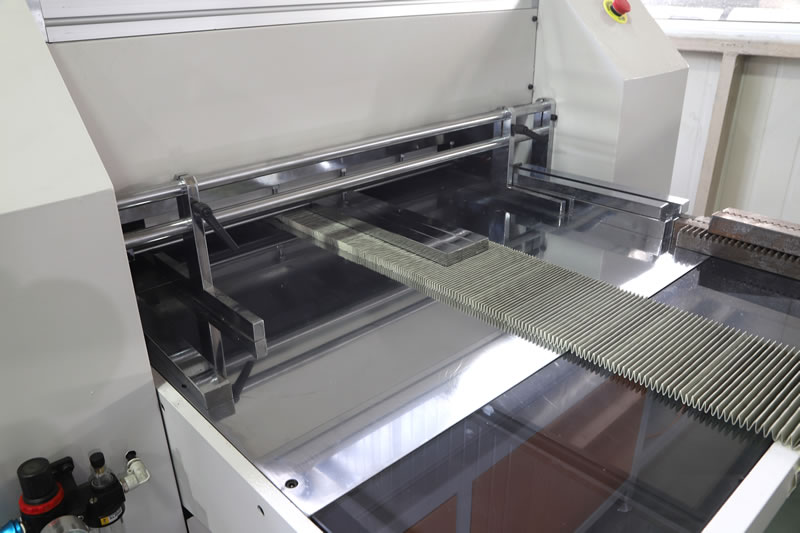

Weaving Workshop

Powder Coating Worshop

Wire Mesh Flattening

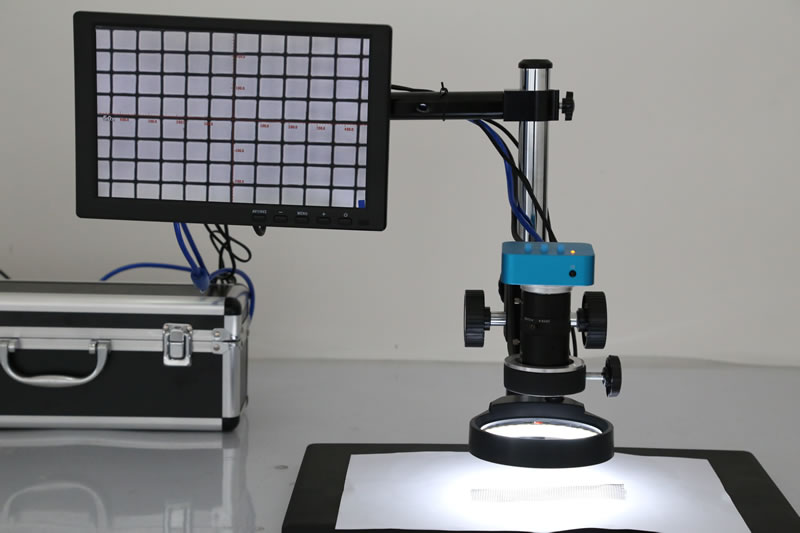

Inspect The Aperture And Wire Dia.

Stripping Test

Oil Immerson Test

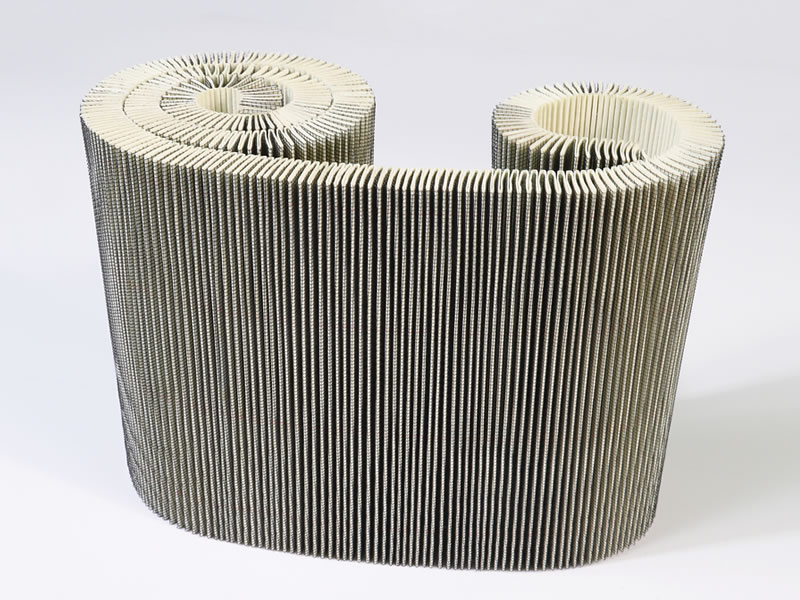

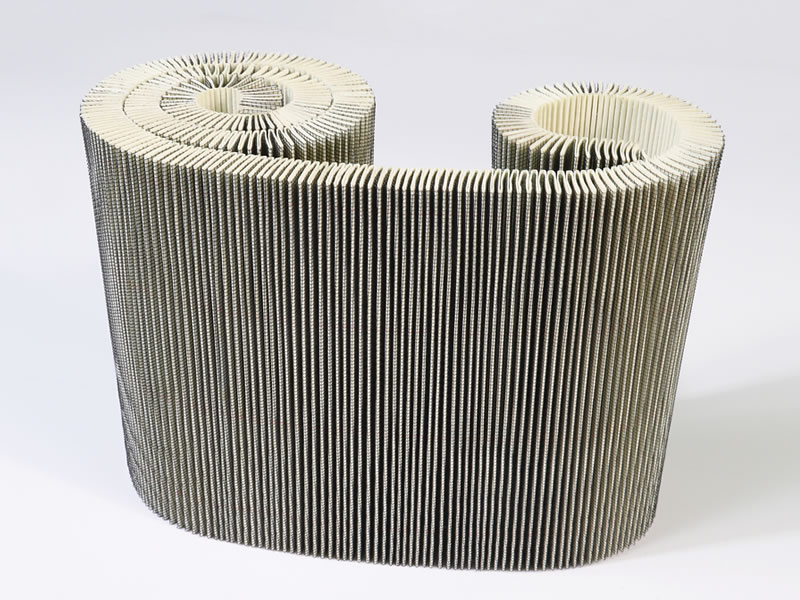

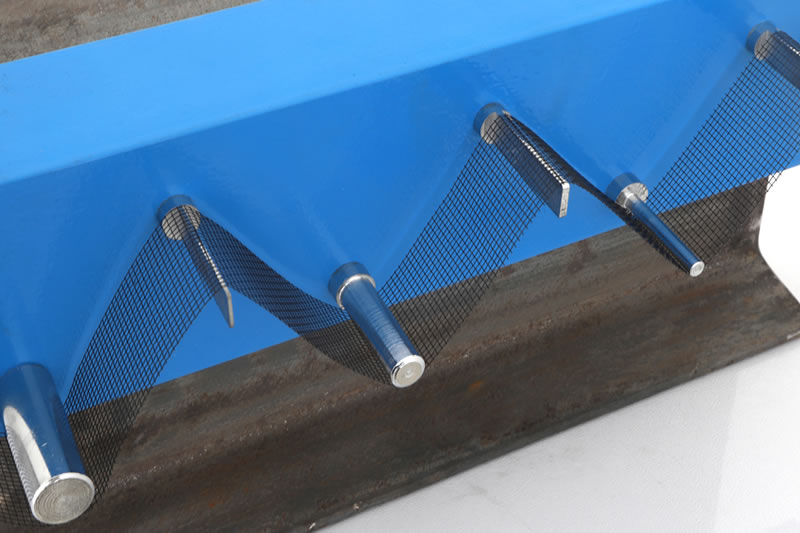

High-Termperature Pleating Test

Elasticity Test

Salt Spray Life Test

Analyze The Raw Material

Inspect The Wire Dia.

Inspect The Tensile Strength

Warehouse

Warehouse

Packing