Started from 1992. Over 30 Years Experience in Metal Weave Wire Mesh.

PRODUCT DETAIL

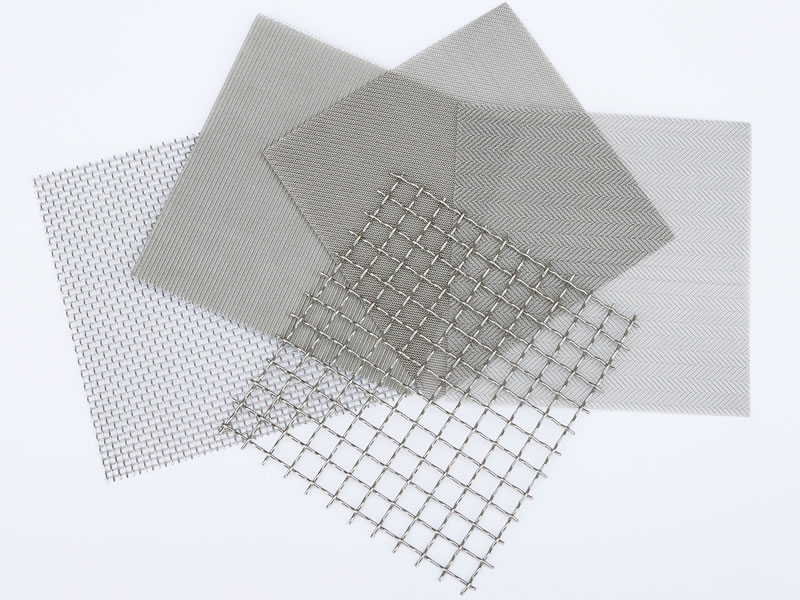

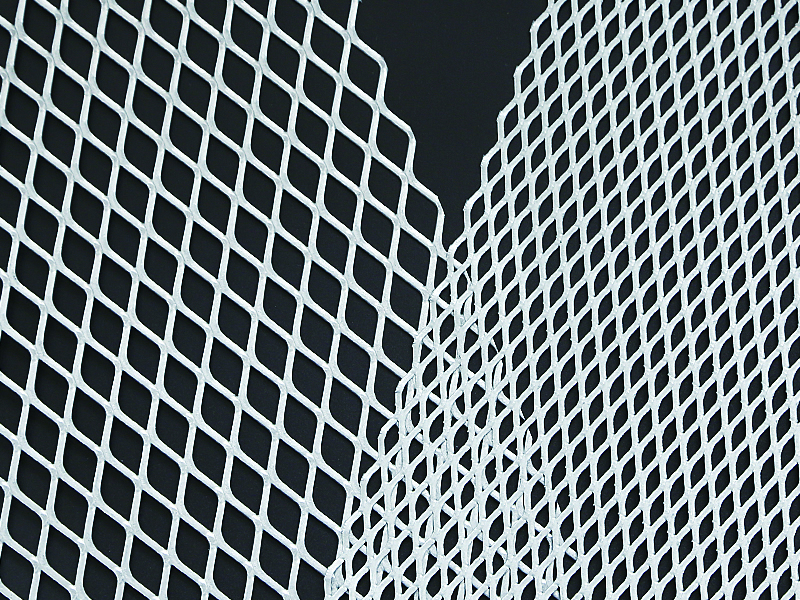

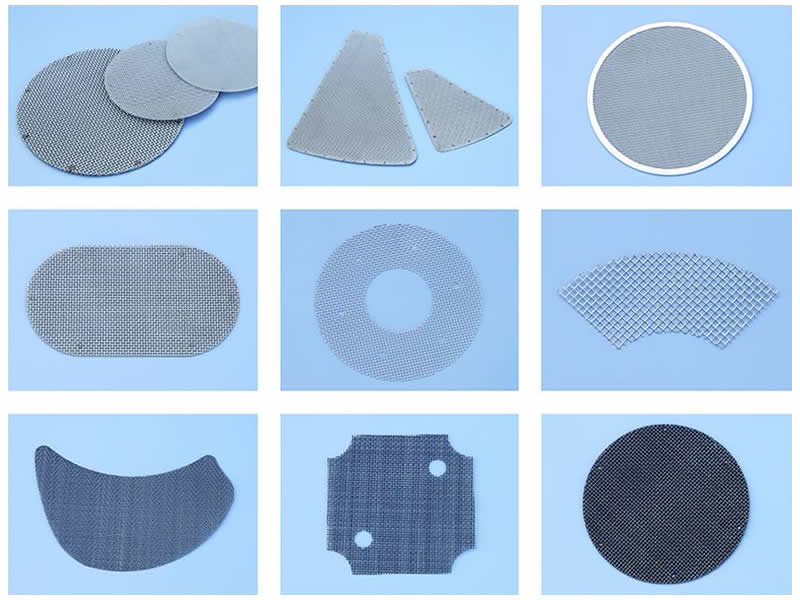

We can provide various materials and shapes of extrude screen. To meet your specific requirements for extrusion processes and polymer melt filtration applications.

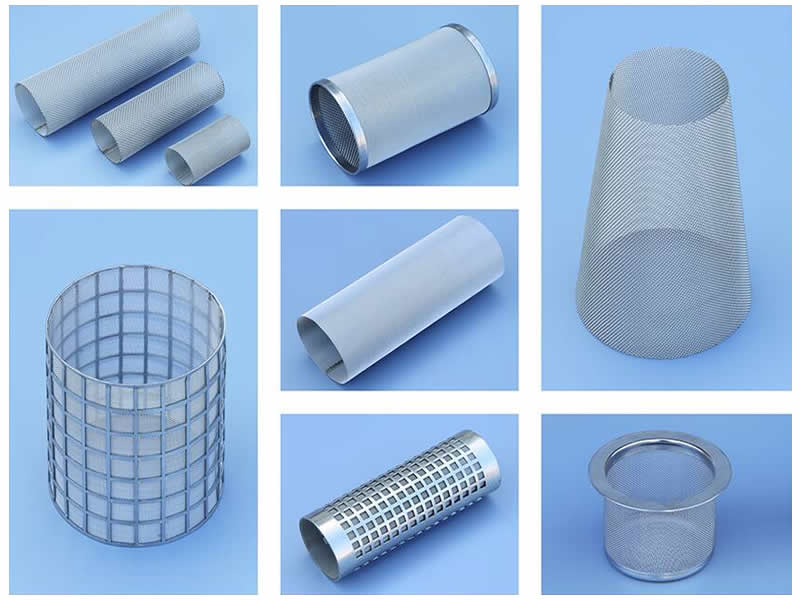

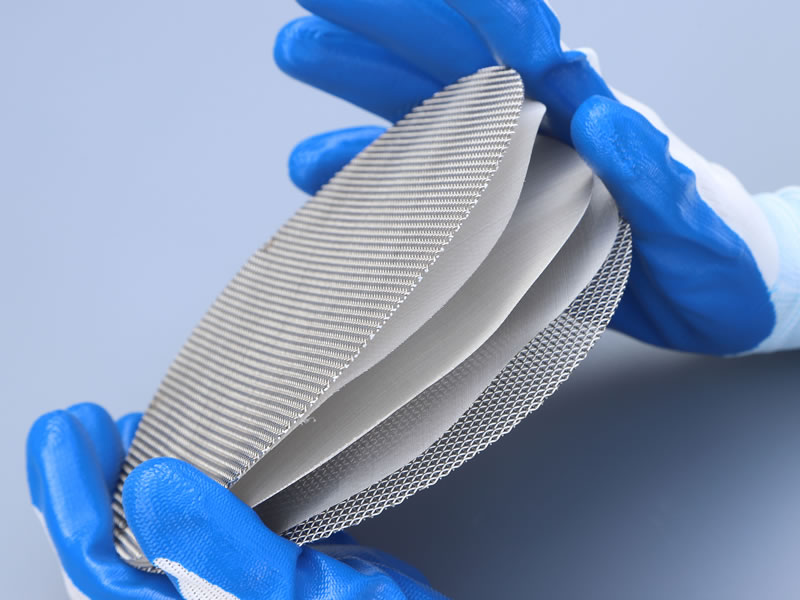

It is single or multilayer with plain weave or twill weave; Circle, round, oval, rectangular, cones, or other special shape can be made with normal mesh spec. 20-500 mesh

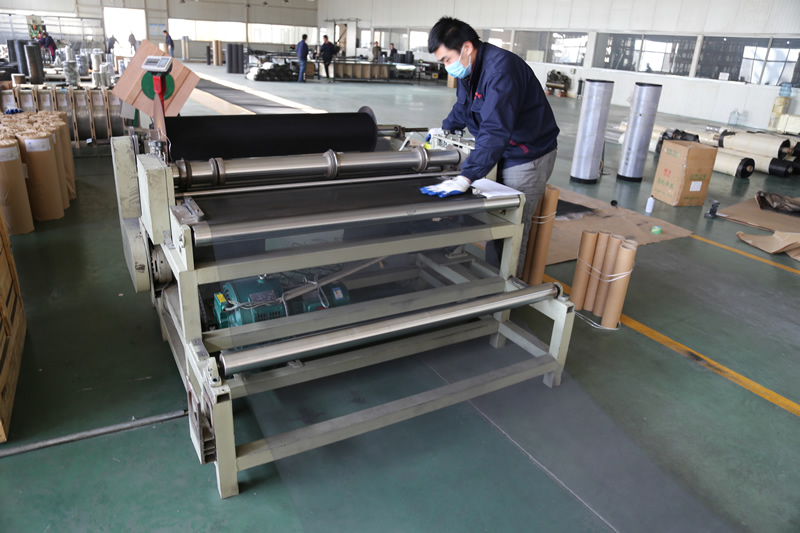

Manufacturing Process

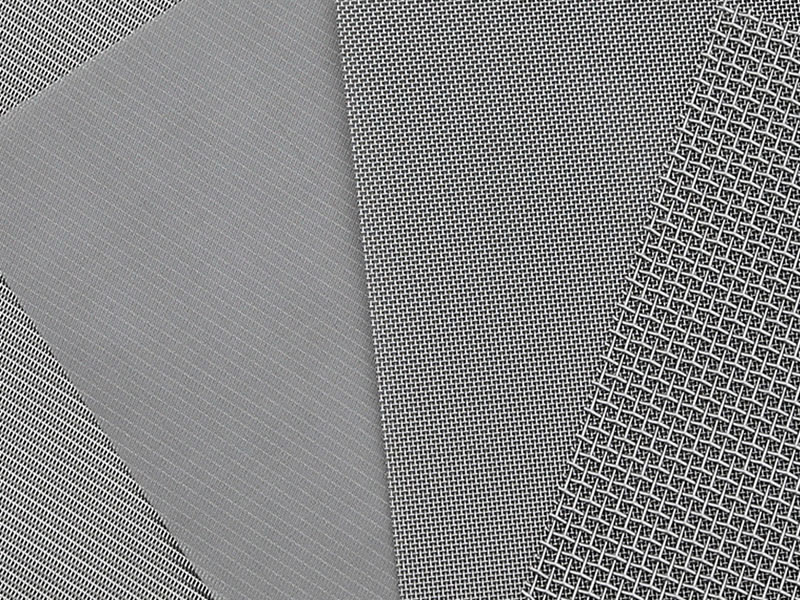

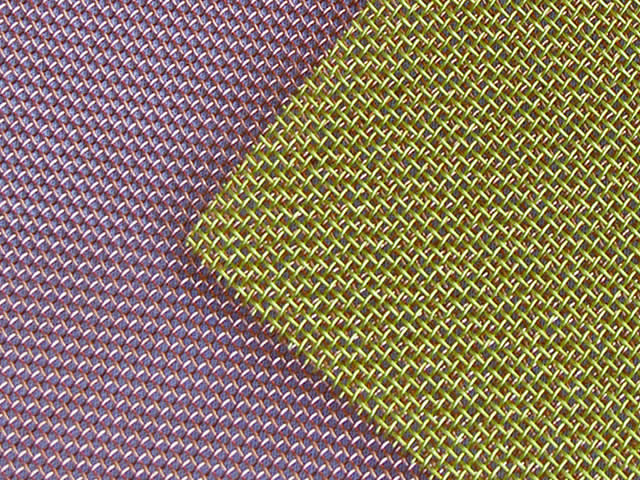

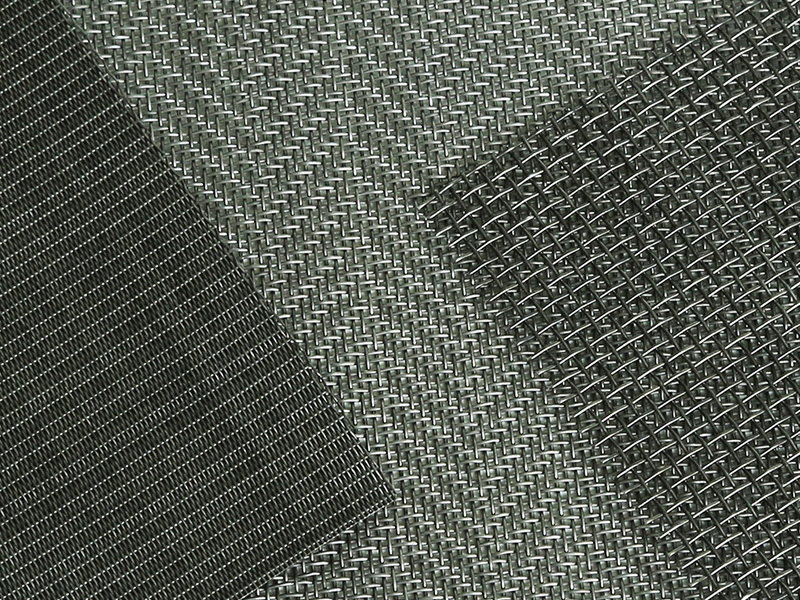

Polymer extruded screen is generally made of plain weave and Dutch weave wire mesh.

Plain weave wire mesh

Features simple structure, economic to process and high cost-effectiveness and can meet the most filtration requirements of plastic products and rubber industries.

Dutch weave wire mesh

Plays the role of fine filtration without requiring a backup filter screen, featuring high strength. High load capacity, simple structure and long service life.

Structure / Working Principle

Polymer extruded screens are widely used for filtration and commingling processes in the production of various viscous materials and products such as plastics, chemical fibers, rubber, hot melt adhesives, adhesives, finishing materials blends, etc, it can effectively prevent foreign matter from mixed in the final plastic and rubber extrusion process and provide a clean, viable extrusion.

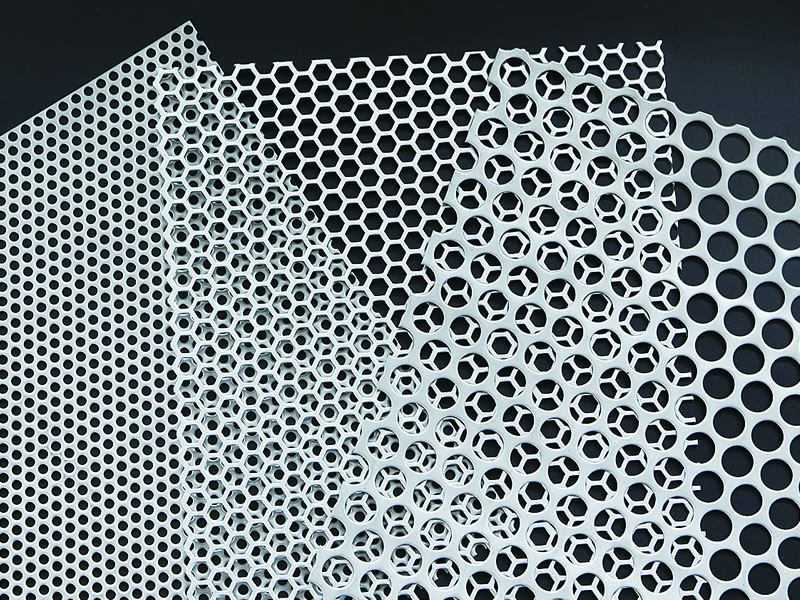

Punching

Multilayer Welding

Welded Cylinder

Vaccuum Annealing Furnace

Cut Strips

Ultrasonic Clean

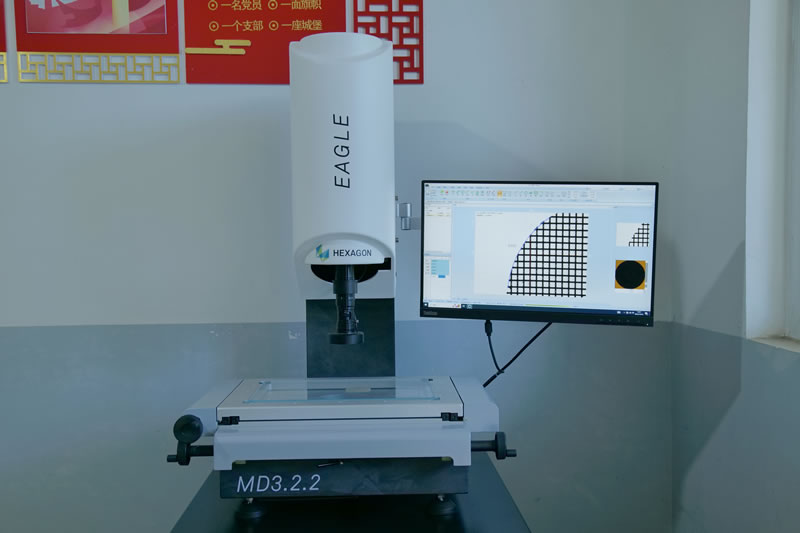

Measure Diameter Of The Discs